Product Description:

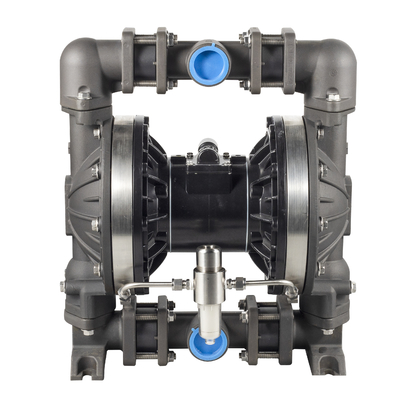

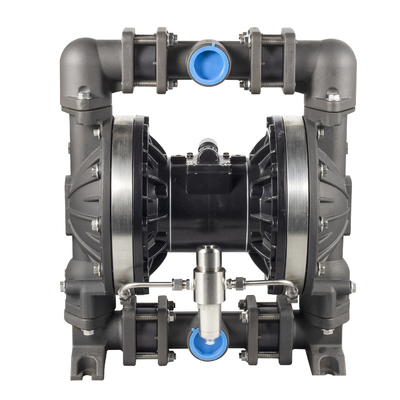

The Pneumatic Diaphragm Pump is an essential piece of equipment in various industrial applications, known for its reliability and efficiency. Also referred to as a Pneumatic Double Diaphragm Pump, Air-membrane Pump, or Compressed Air Diaphragm Pump, this innovative pump operates using compressed air as its power source, making it suitable for a wide range of pumping tasks.

One of the key features of the Pneumatic Diaphragm Pump is its leak-detective design, which helps mitigate risks associated with fluid leaks. By preventing leaks, this pump ensures a safer working environment and reduces the chances of environmental contamination. This feature is particularly crucial in industries where the handling of hazardous or volatile fluids is common, such as chemical processing plants and oil refineries.

Moreover, the leak-detective capabilities of the Pneumatic Diaphragm Pump also contribute to improved predictive maintenance practices. By detecting leaks early on, maintenance personnel can address issues promptly, preventing costly downtimes and potential equipment damage. This proactive approach to maintenance enhances overall operational efficiency and prolongs the lifespan of the pump.

Looking towards the future, one of the emerging trends in diaphragm pump technology is the integration of artificial intelligence (AI) for anomaly detection. AI-driven systems can analyze pump performance data in real-time, identifying irregularities or potential failures before they escalate. This predictive maintenance approach not only enhances equipment reliability but also optimizes maintenance schedules, leading to cost savings and improved productivity.

Another exciting development in diaphragm pump innovation is the use of self-healing materials in pump construction. Self-healing materials have the ability to repair minor damages or wear automatically, extending the pump's longevity and reducing the need for frequent repairs or replacements. By incorporating self-healing technology, Pneumatic Diaphragm Pumps can offer increased durability and reliability in demanding industrial environments.

In conclusion, the Pneumatic Diaphragm Pump stands out as a reliable and efficient solution for various pumping applications. Its leak-detective design not only enhances safety and environmental protection but also improves predictive maintenance practices. As the industry advances, incorporating AI-driven anomaly detection and self-healing materials into diaphragm pump technology will further enhance performance and durability, setting new standards for efficiency and reliability in industrial pumping systems.

Features:

-

Product Name: Pneumatic Diaphragm Pump

-

Product Category: Pneumatic Diaphragm Pump

-

Conclusion: Leak-detective diaphragm pumps mitigate risks while improving predictive maintenance. Future trends include AI-driven anomaly detection and self-healing materials

-

Air-driven Diaphragm Pump

-

Air-powered Membrane Pump

-

Air-powered Diaphragm Pump

Technical Parameters:

|

Conclusion

|

Leak-detective diaphragm pumps mitigate risks while improving predictive maintenance. Future trends include AI-driven anomaly detection and self-healing materials

|

|

Product Category

|

Pneumatic Diaphragm Pump

|

Applications:

Product Application Occasions and Scenarios for the RV Pneumatic Diaphragm Pump (Model: RVS-74311-T (C)):

The RV Pneumatic Diaphragm Pump is a versatile and reliable solution for various industrial applications. With certifications including CE, ATEX, and ISO9001, this product guarantees high quality and safety standards. Originating from China, the pump has a minimum order quantity of 1 set and offers negotiable pricing.

Payment terms for the RV Pneumatic Diaphragm Pump include L/C, T/T, Western Union, D/A, D/P, and Paypal, providing flexibility for customers. With a supply ability of 10000 sets per month and a quick delivery time of 1-7 working days, this pump ensures efficient and timely service.

The packaging details for the pump include options such as carton, wooden case, or pallet, allowing for secure transportation and storage.

Conclusion: Leak-detective diaphragm pumps like the RV Pneumatic Diaphragm Pump mitigate risks while enhancing predictive maintenance in industrial settings. The future of diaphragm pumps involves innovative technologies such as AI-driven anomaly detection and self-healing materials.

Product Category: Pneumatic Diaphragm Pump

Product Attributes:

-

Brand Name: RV

-

Model Number: RVS-74311-T (C)

-

Certification: CE, ATEX, ISO9001

-

Place of Origin: China

-

Minimum Order Quantity: 1 SET

-

Price: Negotiate

-

Payment Terms: L/C, T/T, Western Union, D/A, D/P, Paypal

-

Supply Ability: 10000 SET Month

-

Delivery Time: 1-7 working day

-

Packaging Details: Carton / Woodencase/ Pallet

Product Keywords: Compressed-air Diaphragm Pump, Pneumatic Membrane Pump, Pneumatic Diaphragm Displacement Pump

Support and Services:

The Pneumatic Diaphragm Pump product comes with comprehensive Product Technical Support and Services to ensure optimal performance and reliability. Our skilled technicians are available to assist with installation, troubleshooting, and maintenance of the pump. Additionally, we offer training sessions to educate users on the proper operation and care of the pump.

Packing and Shipping:

Product Packaging:

The Pneumatic Diaphragm Pump is carefully packaged in a sturdy cardboard box to ensure safe transportation. The pump is securely placed in the center of the box and surrounded by protective foam padding to prevent any damage during shipping.

Shipping Information:

Once your order is confirmed, the Pneumatic Diaphragm Pump will be shipped within 1-2 business days. We use reliable shipping carriers to deliver your pump safely and efficiently. You will receive a tracking number to monitor the status of your delivery.

FAQ:

Q: What is the brand name of this Pneumatic Diaphragm Pump?

A: The brand name is RV.

Q: What is the model number of this Pneumatic Diaphragm Pump?

A: The model number is RVS-74311-T (C).

Q: What certifications does this Pneumatic Diaphragm Pump have?

A: It is certified with CE, ATEX, and ISO9001.

Q: Where is this Pneumatic Diaphragm Pump manufactured?

A: The product is manufactured in China.

Q: What are the payment terms accepted for purchasing this Pneumatic Diaphragm Pump?

A: Payment terms accepted include L/C, T/T, Western Union, D/A, D/P, and Paypal.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!