Product Description:

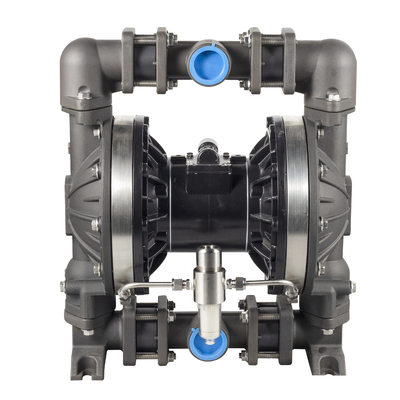

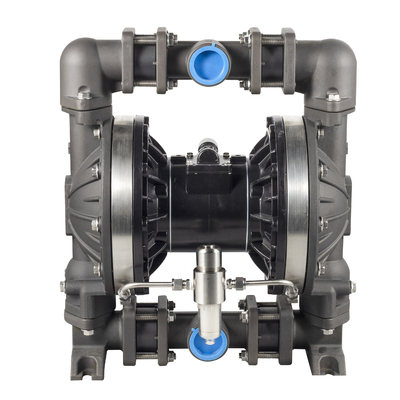

Are you in need of a reliable and efficient solution for your pumping needs? Look no further than our top-of-the-line Pneumatic Diaphragm Pump! This innovative product falls under the category of Air-driven Diaphragm Pump, providing exceptional performance and versatility for various applications.

Known for its exceptional leak-detective capabilities, the Pneumatic Diaphragm Pump is designed to mitigate risks associated with fluid transfer operations. Its advanced diaphragm technology ensures a secure and reliable pumping process, minimizing the chances of leaks and spills that could lead to costly downtime and environmental hazards.

One of the key features of our Pneumatic Diaphragm Pump is its dual diaphragm design, making it a Pneumatic Double Diaphragm Pump. This unique configuration enhances the pump's efficiency and durability, allowing for continuous operation even in demanding environments. With its air-powered mechanism, this pump delivers consistent performance without the need for external power sources, making it a cost-effective and energy-efficient solution.

Moreover, the Pneumatic Diaphragm Pump excels in predictive maintenance, allowing users to anticipate potential issues before they escalate. By monitoring diaphragm performance and detecting anomalies in real-time, this pump enables proactive maintenance practices that help prevent unexpected breakdowns and extend equipment lifespan.

As the industry continues to evolve, future trends in diaphragm pump technology are poised to revolutionize fluid handling operations. With the integration of AI-driven anomaly detection systems, pumps like our Pneumatic Diaphragm Pump will be able to analyze performance data and identify potential issues with unprecedented accuracy. This predictive maintenance approach will further enhance operational efficiency and reduce maintenance costs.

Another exciting development on the horizon is the use of self-healing materials in diaphragm pump construction. By incorporating advanced materials that can repair minor damages automatically, pumps will become more resilient and reliable, minimizing downtime and extending service intervals. This innovation will drive significant advancements in pump reliability and performance, setting new standards for fluid transfer systems.

In conclusion, our Pneumatic Diaphragm Pump stands out as a cutting-edge solution that combines leak-detective technology, predictive maintenance capabilities, and energy-efficient operation. As the industry embraces future trends such as AI-driven anomaly detection and self-healing materials, this pump is poised to lead the way in improving operational efficiency and reducing maintenance costs. Experience the next level of pumping performance with our top-of-the-line Pneumatic Diaphragm Pump!

Features:

-

Product Name: Pneumatic Diaphragm Pump

-

Product Category: Pneumatic Diaphragm Pump

-

Conclusion: Leak-detective diaphragm pumps mitigate risks while improving predictive maintenance. Future trends include AI-driven anomaly detection and self-healing materials

-

7. Air-membrane Pump

-

7. Air-membrane Pump

-

1. Air-operated Diaphragm Pump

Technical Parameters:

|

Product Category

|

Pneumatic Diaphragm Pump

|

|

Conclusion

|

Leak-detective diaphragm pumps mitigate risks while improving predictive maintenance. Future trends include AI-driven anomaly detection and self-healing materials

|

Applications:

Product Application Occasions and Scenarios for RV Pneumatic Diaphragm Pump:

The RV Pneumatic Diaphragm Pump, model RVS-74311-T (C), is a versatile and reliable solution suitable for various industries and applications.

1. Industrial Manufacturing: The RV Pneumatic Diaphragm Pump is ideal for transferring fluids in industrial manufacturing processes. Its robust design and efficient operation make it suitable for handling a wide range of liquids, from chemicals to wastewater.

2. Petrochemical Industry: With CE, ATEX, and ISO9001 certifications, the RV Pneumatic Diaphragm Pump meets the stringent safety and quality standards required in the petrochemical industry. Its leak-detective features ensure secure fluid transfer, reducing the risk of spills and contamination.

3. Mining and Construction: The RV Pneumatic Diaphragm Pump is well-suited for handling abrasive fluids in mining and construction applications. Its pneumatic diaphragm displacement pump design allows for efficient pumping of thick sludges and slurries.

4. Food and Beverage: The RV Pneumatic Diaphragm Pump is safe for use in the food and beverage industry, thanks to its high-quality materials and hygienic design. It can handle a variety of food products, from juices to sauces, with ease.

5. Environmental Protection: The air-driven diaphragm pump technology of the RV pump makes it an eco-friendly choice for environmental protection applications. Its self-healing materials ensure long-lasting performance, reducing maintenance downtime.

6. Agriculture: Farmers can benefit from the RV Pneumatic Diaphragm Pump for irrigation, fertilization, and pesticide application. Its reliable operation and easy maintenance make it a valuable tool in agricultural settings.

7. Automotive Industry: The RV Pneumatic Diaphragm Pump can be used for transferring oils, coolants, and other fluids in automotive manufacturing and repair facilities. Its compact size and efficient performance make it a convenient choice for automotive applications.

8. Pharmaceutical Sector: With a minimum order quantity of 1 set and flexible payment terms including L/C, T/T, and Paypal, the RV Pneumatic Diaphragm Pump is a cost-effective solution for pharmaceutical companies. Its precise fluid handling capabilities meet the strict requirements of the pharmaceutical sector.

9. Water Treatment: The RV Pneumatic Diaphragm Pump is suitable for water treatment applications, such as sewage treatment plants and desalination facilities. Its supply ability of 10000 sets per month ensures timely delivery for critical water treatment processes.

10. Future Trends: As technology advances, the RV Pneumatic Diaphragm Pump is expected to incorporate AI-driven anomaly detection and self-healing materials. These innovations will further enhance its performance and reliability, making it a top choice for predictive maintenance applications.

Whether it's for industrial manufacturing, petrochemical processes, or environmental protection, the RV Pneumatic Diaphragm Pump offers a leak-detective solution that mitigates risks and improves operational efficiency.

Support and Services:

The Product Technical Support and Services for the Pneumatic Diaphragm Pump include:

- Installation assistance

- Troubleshooting guidance

- Maintenance recommendations

- Repair services

- Training programs

Packing and Shipping:

Product Packaging for Pneumatic Diaphragm Pump:

The pneumatic diaphragm pump will be securely packaged in a sturdy cardboard box with protective foam padding to prevent damage during transit.

Shipping Information:

The product will be shipped via a reputable carrier such as UPS or FedEx. Customers can expect their order to be delivered within 3-5 business days, with tracking information provided for easy monitoring of the shipment status.

FAQ:

Q: What is the brand name of the Pneumatic Diaphragm Pump?

A: The brand name is RV.

Q: What is the model number of the Pneumatic Diaphragm Pump?

A: The model number is RVS-74311-T (C).

Q: What certifications does the Pneumatic Diaphragm Pump have?

A: The pump is certified with CE, ATEX, and ISO9001.

Q: Where is the Pneumatic Diaphragm Pump manufactured?

A: The pump is manufactured in China.

Q: What are the available payment terms for purchasing the Pneumatic Diaphragm Pump?

A: Payment terms include L/C, T/T, Western Union, D/A, D/P, and Paypal.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!